El Laboratorio de Mecánica Aplicada SEAT-IQS se ha visto ampliado con la reciente incorporación de un microscopio digital Olympus DSX1000 de alta resolución, para el análisis de superficies, texturas y fracturas en muestras de componentes industriales.

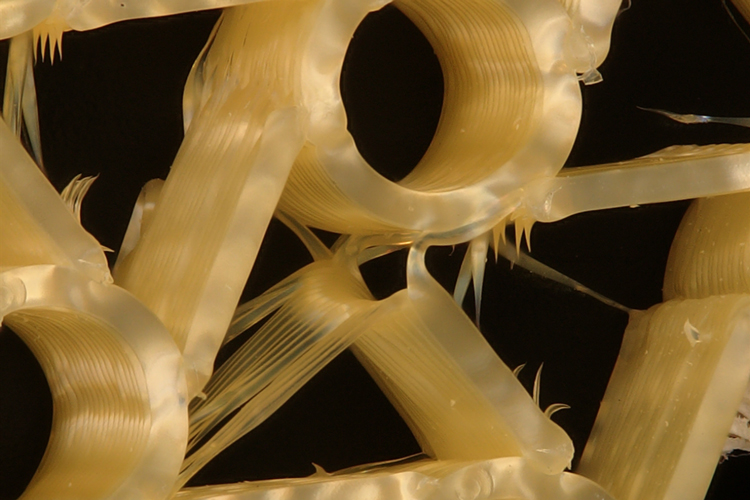

Microscopic detail of a cellular solid manufactured with 3D printing

The SEAT-IQS Applied Mechanics Laboratory within the IQS School of Engineering Industrial Engineering Department has recently acquired a new Olympus DSX1000 digital microscope, the latest addition to the various advanced inspection and non-destructive analysis equipment that the laboratory features.

The microscope is a high resolution digital device that is fully motorized and features a tilting moving head. It is equipped with specific software that facilitates the three-dimensional analysis of surfaces, textures, and fractures, among others.

Additive manufacturing component applications

In general, manufacturing parts with AD/3D requires a complete analysis of the parts, including their quality and detecting possible manufacturing defects.

One of the specific fields of application for this new device is analysing defects in advanced components manufactured with 3D printing, an area in which the researchers with the Industrial Products Engineering Group (GEPI) at IQS have extensive experience.

Currently, this research group is working on improving the surface finish of printed structural components through fused deposition modelling with ULTEM® thermoplastic based on new mechanical, chemical, and thermal post-processing techniques.

In short, the new digital microscope is a versatile, high-performance device with countless applications that complements the range of analysis and inspection techniques at the SEAT-IQS laboratory within the IQS Industrial Engineering Department.