Bioprocessing infrastructure and equipment for the development, optimisation, scale-up and manufacturing of test batches. Suitable for microorganisms cultures (bacteria, yeasts and fungi) in batch and fed-batch and in aerobic or anaerobic conditions. Class 1 organisms (non-pathogenic). Includes downstream operations for the first stages of bioproduct isolation.

Equipment and technologies

It features a surface area of 130 m2 including:

- Bioprocessing space, which houses the 144 L bioreactor, auxiliary services and process equipment (DSP) including cell disruption, centrifugation, microfiltration, ultrafiltration and lyophilisation.

- Reagents and Product storage, with a 4ºC cold chamber and a -20C chest for the storage of samples, culture media and production batches that require cold preservation.

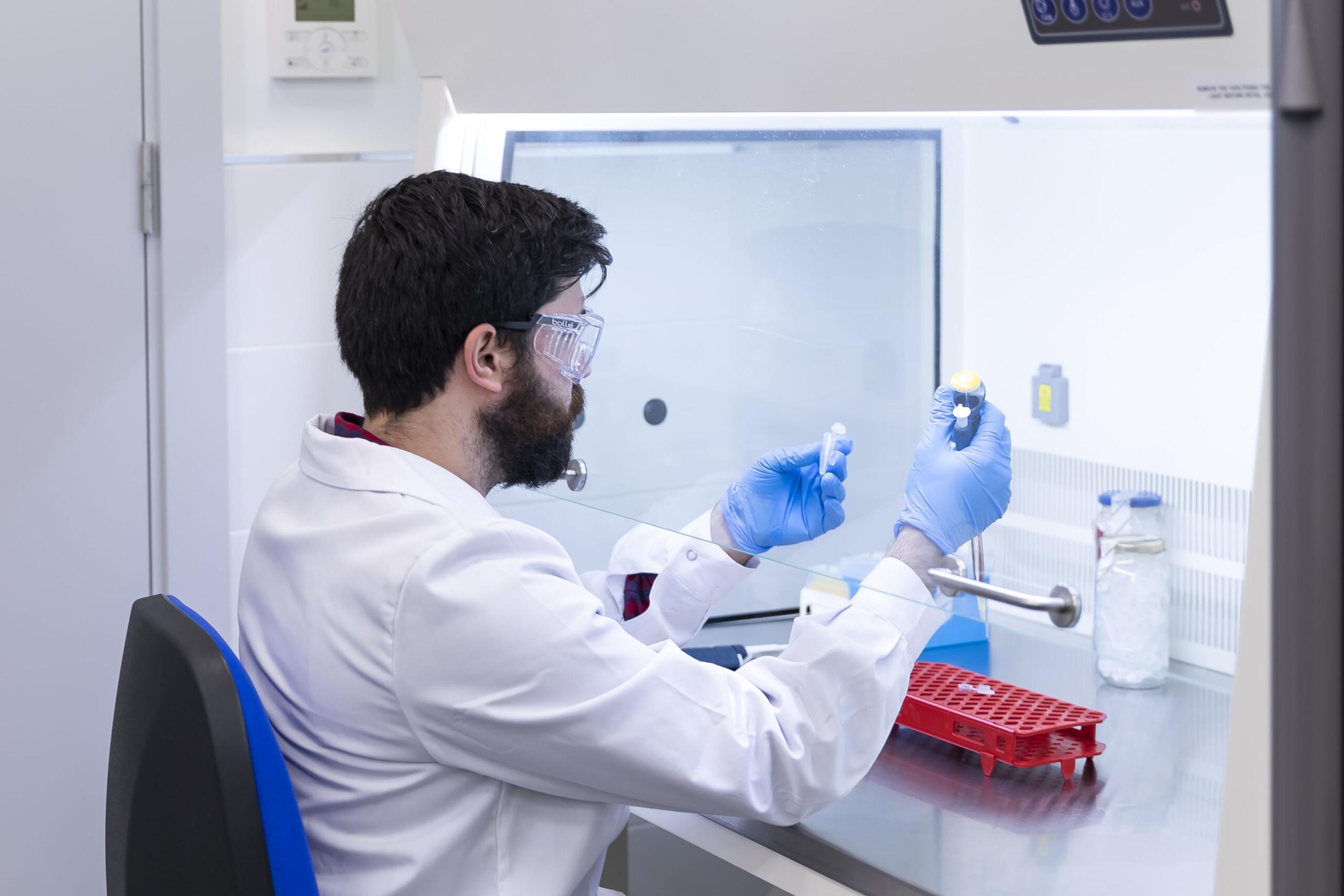

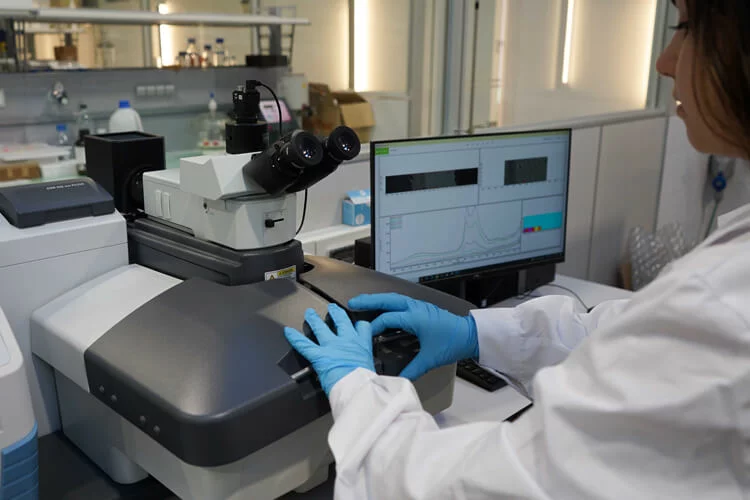

- Auxiliary Laboratory, for the preparation of inoculums, culture media and analytical techniques. Equipped with a laminar flow cabinet, fume hood, incubators, baths, centrifuges, spectrophotometer, analyser, and a 10 L bioreactor for inoculum preparation and for preliminary viability and optimisation studies.

144L Biorecator: Bioreactor for cultures, with a net volume going from 20 to 100 L. (Bionet, model F3-100)

Equipment and technologies

- 144 L Bioreactor (Bionet)

- 10 L Bioreactor (Bionet)

- Tangential microfiltration and ultrafiltration system (Bionet)

- Cell disruptor (Gea Niro Soavi)

- Process centrifuge (Alfa Laval)

- Freeze dryer with chamber (Coolvacuum)