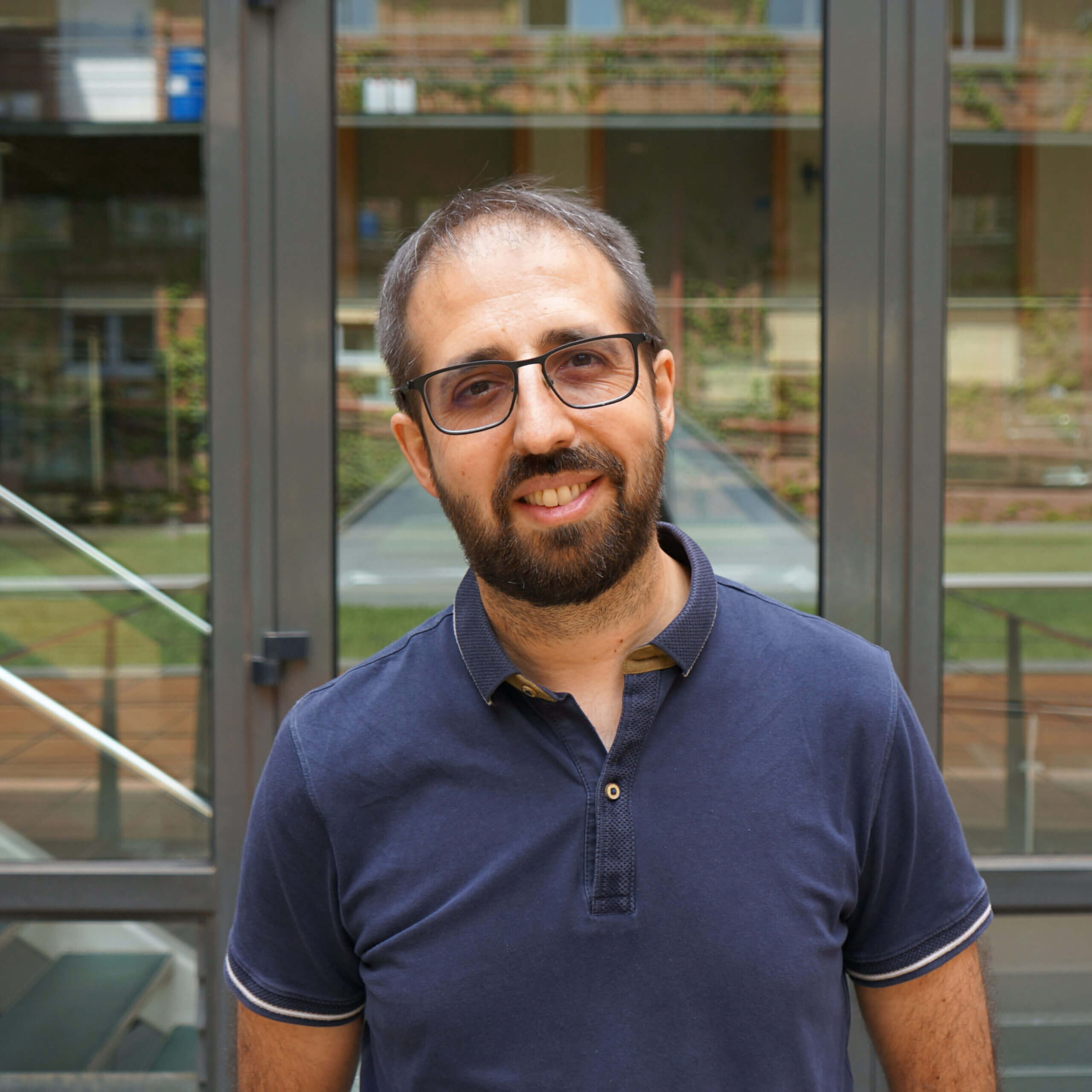

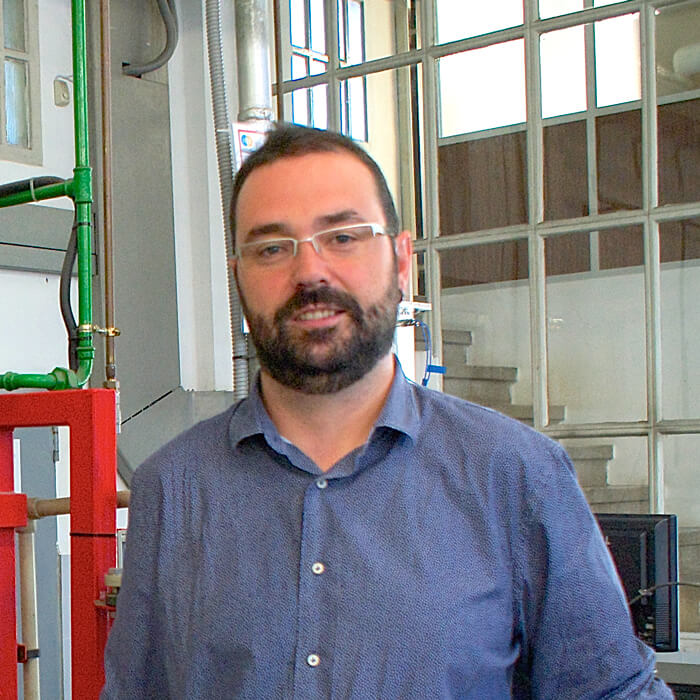

If you want to discover what university life is like at IQS and find out all the details about this master’s degree, who better to tell you about it than our students?

At IQS, each student is a story of motivation, dedication, and success. Through their experiences, you’ll be able to get a more accurate view on the master’s degree, the subjects taught, and the professional impact it has on students.