The saturation of patients due to the expansion of Covid-19 in Spain is leading Spanish hospitals to an extreme situation of need for material for health professionals. Given this situation, the scientific community has come together to quickly create products that can alleviate the situation in the shortest possible time.

The saturation of patients due to the spread of Covid-19 in Spain has caused a serious shortage of materials for health care professionals in Spanish hospitals. Faced with this situation, the scientific community has joined together to quickly create products that can help alleviate the situation in the shortest time possible.

IQS is part of the community of makers that have organised an entire network to receive requests from hospitals, create and validate designs, optimise manufacturing parameters, produce parts and coordinate logistics to distribute the products to hospitals. Several projects are in progress in this community from protective elements for medical teams to creating parts and even assisted breathing devices.

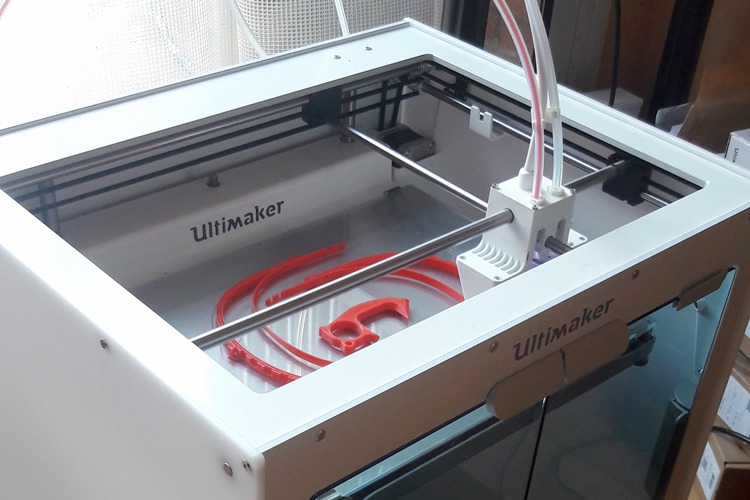

Many different organisations are promoting these initiatives: the association of engineers, technological centres like Leitat and Eurecat, and private companies like HP and SEAT, among others, have all started manufacturing devices. IQS is currently manufacturing protective masks for medical teams using 3D printers, including, among others, the Ultimaker S5 that the university has received thanks to the donation by the Maria Francisca de Roviralta Foundation through the Fundació Empreses IQS.

Several professors from the Department of Industrial Engineering and other departments at the IQS School of Engineering have already reacted to this need and have started purchasing 3D printers for their homes that they can use to produce devices that can cover some of our hospital's many needs at this important time.